Why Investing in HTD Timing Belts is a Wise Advice for Versatile Applications

High accuracy, long-lasting longevity, and dependability guarantee that equipment runs with minimal glitches in today’s advanced technologies. Perhaps surprisingly, timing belts bear critical responsibility in these roles. The most famous type is the HTD (High Torque Drive) timing belt, which has strong traverse performance and high working efficiency. Let’s explore why businesses and industries should incorporate HTD Timing Belts into their systems.

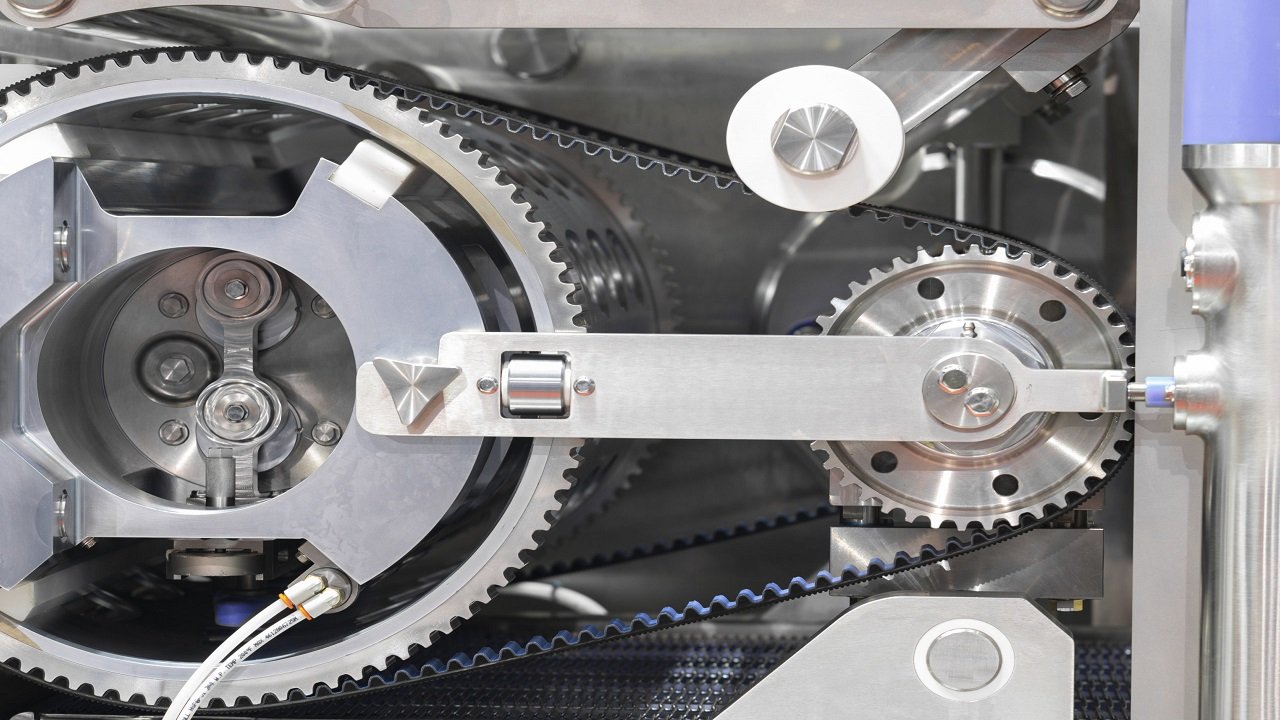

Superior Load Capacity

In fact, against the trapezoidal profile, HTD timing belts provide even more load-carrying ability. The more complex structure of the teeth supplies a larger resistant surface, allowing these belts to bear large torque. This makes them especially ideal for high-performance products that call for complementary operation of mechanical parts. The upgraded HTD timing belts should benefit industries, including robotics, machine tools, and automotive manufacturing.

Improved Performance and Efficiency

Due to the cogged-shaped tooth design, the HTD belt can increase the contact face area of the pulley. This increased contact area minimizes the normally present slide, thus making it easier to run the whole system and increasing the chances of better performance. This, in turn, means that machines function better, utilize less energy and energy retaining or cycle more slowly, and do not incur frequent repairs. This can drastically cut operations costs in multiple fields, such as food processing, data storage, and vacuum cleaner manufacturing.

Reduced Bearing Loads

HTD timing belts are planned to run under reduced installation tension. This lessens bearing loads considerably, enhancing the lives of bearings and other relevant parts. Since there is less stress on the bearings, the machinery undergoes little usage wear and tear; hence, little maintenance is needed, and it will last longer. It is most useful in construction, mining, and agriculture through manufacturing equipment with heavy loads for long durations.

More Durability and Strength

HTD timing belts possess deeper, proportionally bigger teeth with more shear strength. This increased strength means the belts can handle much harder work—especially in high-torque usage. As a result of their durability, HTD belts can provide long hours of operation without necessitating frequent replacement. This added longevity makes them a cheaper option, particularly for industries where any break in production will mean lots of money lost on production and other processes.

Reduced Risk of Tooth Jumping

HTD timing belts are characterized by the teeth being cut off as deep as the belt’s width. This helps to reduce the teeth’ expedition, where they interlock or lose their positional orientation relative to one another—a problem that results in operational challenges such as misfitting or failure. This benefit is especially crucial in manufacturing activities requiring high accuracy, such as medical equipment, office machines, and robots.

Conclusion

HTD timing belts support adequate business performance, reduce expenses, and maintain long-lasting machinery in high operational capacity. They provide higher load-carrying capacity, greater wear and tear resistance, and higher efficiency, making them affordable assets for manufacturing, robotics, and other applications. Using HTD timing belts assures that the business’s output will not be hampered while consuming the least cash for long-term running.