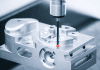

Design Details Of The Parts

Machined parts are undercuts in an object that is impossible to make using standard chopping equipment. Unlike molded parts, they are working piece elements, which could indeed handle low ceilings and distort when they’re too rigid.

Steep projecting parts, such as narrow sides, are hard to manufacture because the chopping device’s oscillations can destroy the segment or decrease reliability. Since CNC manufactured components are manufactured inside the processor’s proposed site, their size is restricted.

Substances For Manufactured Surfaces

Manufactured objects can be coated to change their external sensory properties upon milling. There was no enhanced surface treatment earlier. Numerous intrinsic, quasi functionalities can be used in this manner.

Granular material is fired at the manufactured object during the beaded machining operation, rendering it matt. The electrolytic oxide layer procedure of anodic oxidation creates a blemish, colorful covering with milled aluminum items. The finely ground pigment is sprinkled over the manufactured article, subsequently cooked in a furnace.

Molded Pieces Have A Variety Of Uses

Experimental machined parts, fuel screens, undercarriage elements, and ignition coils are all cutting tools aviation items used in manufacturing. Illumination, powertrain, gearbox, navigation units, and yet other customized pieces are examples of automobile machinability.

Fasteners, healthcare gadgets, and microsurgery such as razor blades are all made from milled titanium and alloy steel elements.

Utilities

- Among the enormous benefits of machinability is that there is no minimum bid volume.

- Several manufacturing businesses like to buy injected molded samples, but only significant corporations can finance to do so. Replication might be incredibly costly given the cost of manufacturing.

- Chamfered components are available in a wide range of shapes and sizes. It’s due to the fact that Mold limitations do not constrain economic output.

- Molded components are made to a desired level of precision. Consumers can set parameters that must be satisfied by the manufacturer, which is somewhat more significant.

- Anodized elements can be created more quickly than those made through other methods, such as shaping. This is because of the lack of laborious machinery, but the fabrication is also quite effective.

- Since CNC manufactured materials from a computerized CAD file, adjustments to the computer fabrication are feasible.

Service Details

The amenity of CNC Milling

CNC milling, mainly five-axis grinding and polishing, can construct complicated 3 Dimension designs or impart a surface quality or embellishments to polycarbonate items.

Molding in a void

Void casting and silicon molding are two of its specialties. Designers can create rigid thermoplastics to the required level cost-effectively and quickly, thanks to generations of experience in the industry.

Instruments for Speedy Tooling

That’s a quick and affordable technique to do minimal mold on a range of disposable items.

Molded Products Insertion

Quick turnover on elevated experimental paneling made from aluminum molds. Users can put their innovations to the test regarding ease of manufacture and usefulness.

Metal Welding on the Spot

Elevated press molding in aluminum, mg, and zinc, along with investments castings in metal and all kinds of metal, are now available.

Construction of Metal Forming Prototypes

Bespoke structural steel prototyping offerings are a quick and price alternative for your tasks.